PRODUCTS

CONTACTS

Tel/WhatsApp: +8613315790503

Email: admin@shunlinfeng.com

Address: Yanshan County, Cangzhou, Hebei Province, China

High-Pressure Threaded Tee

Keyword:

Product Detail

Standard

Product introduction

High-Pressure Threaded Tee Technical Overview

A high-pressure threaded tee is a specialized pipe fitting designed to create secure 90-degree branch connections in piping systems operating under extreme pressure conditions. This robust fitting features three female threaded openings (typically NPT or BSPT) arranged in a T-configuration, engineered to withstand working pressures up to 10,000 psi in standard configurations, with special designs available for even higher pressure applications.

Manufactured from high-grade materials such as ASTM A105 carbon steel, A182 stainless steels (F304/F316), or high-yield alloy steels, these tees undergo rigorous heat treatment and machining processes to ensure optimal strength and pressure containment. The threaded design eliminates welding requirements while providing a reliable mechanical connection that can be disassembled for maintenance or system modifications.

Key design characteristics include:

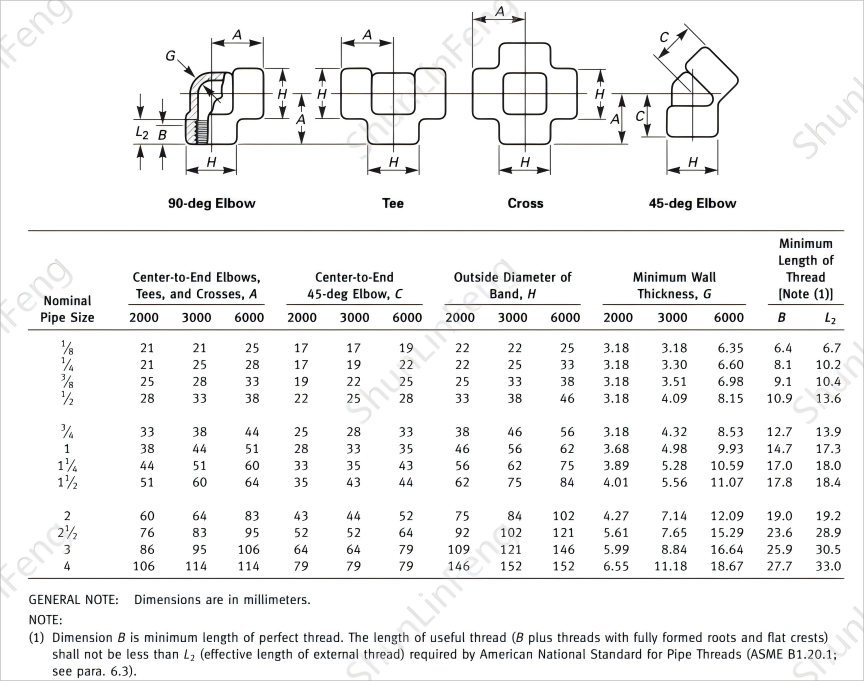

Precision-cut tapered threads meeting ASME B1.20.1 specifications

Reinforced body construction with extra material at branch intersections

Smooth internal transitions to minimize turbulence and pressure drop

Full-depth thread engagement for maximum joint strength

Installation requires careful attention to:

Proper thread cleaning and application of high-pressure sealant

Sequential tightening of connections to balance stress distribution

Torque control to prevent thread galling or deformation

Post-installation pressure testing to verify seal integrity

These high-pressure tees find critical applications in:

Oil and gas wellhead control systems

Hydraulic power units and accumulator systems

High-pressure chemical injection lines

Power plant steam and feedwater systems

Industrial process piping with cyclic pressure loads

Quality assurance measures include:

100% material certification to ASTM specifications

Dimensional verification per ASME B16.11 standards

Hydrostatic testing at 1.5 times working pressure

Non-destructive examination for critical service applications

Specialized versions may feature:

NACE-compliant materials for sour service

Corrosion-resistant overlays for aggressive media

Integral pressure relief ports

Custom thread configurations for unique system requirements

The high-pressure threaded tee's combination of mechanical strength, pressure integrity, and installation flexibility makes it an essential component in critical piping systems where welded connections are impractical or where future maintenance access may be required. Its design represents an optimal balance between connection reliability and system serviceability under extreme operating conditions.

Factory

Product packaging

We can provide wooden box packaging, pallet packaging, carton box packaging, and we can accept customized packaging.

FAQ

Q:Can I Get A Sample For Testing?

A:Yes, We Can Provide Free Samples, But You Need To Pay For The Shipping Cost.

Q:Is It Safe On The Payment For Me As We Are The First Cooperation?

A:We Can Do The Trade Assurance , Which Will Guarantee Your Payment Safety, We Also Accept Other Safe Payment Way As You Want.

Q:Do You Accept Product Customization?

A:Yes, We Can Accept Material Customization, Specification Model Customization, Drawing Customization, Packaging Customization.

Q:Can I Put Our Logo On The Product?

A:Yes, We Can Provide You With Laser Engraving Logo And Sticker Logo For Free.

Q:What Is The Moq?

A:For Trial Order, We Can Sell Even One Piece

Q:How Long Is The Product Warranty Period?

A:One Year, If The Product Is Non-Artificially Damaged During The Warranty Period, We Can Provide You With A New Product For Free.

Q:How Long Is The Delivery Time?

A:If We Have Stock, We Will Ship Within 2 Days, If There Is No Stock, We Will Ship Within 5-7 Days.

Q:Do You Accept Oem/Odm Service?

A:Yes, We Can Produce Products According To Your Requirements.

Related Products

Product Consultation

We will contact you within one working day. Please pay attention to your email.