PRODUCTS

CONTACTS

Tel/WhatsApp: +8613315790503

Email: admin@shunlinfeng.com

Address: Yanshan County, Cangzhou, Hebei Province, China

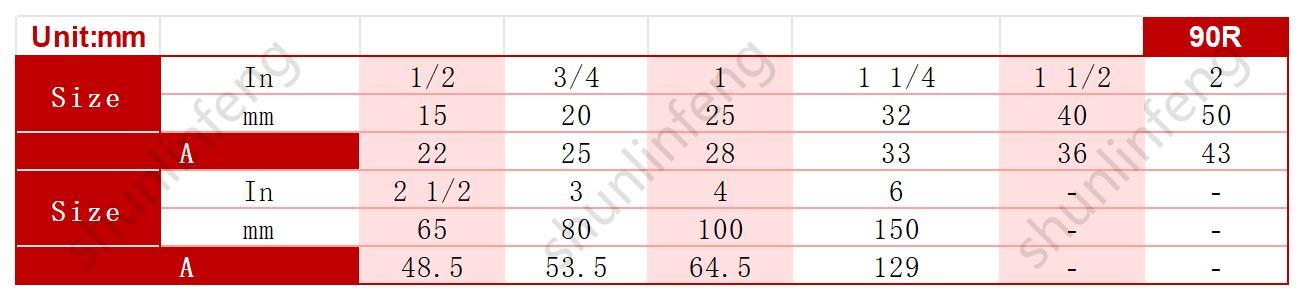

Internal thread 90 degree elbow

Keyword:

Product Detail

Standard

Product introduction

Product introduction

Internal Thread 90-Degree Elbow

An Internal Thread 90-Degree Elbow is a pipe fitting designed to change the direction of flow by 90 degrees while featuring female (internal) threads on both ends for easy screw-type installation. These elbows are commonly used in low-to-medium pressure piping systems where welding is impractical or disassembly may be required for maintenance.

Key Features & Specifications

1. Design & Construction

- 90° Direction Change: Provides a right-angle turn in piping systems.

- Internal Threads (Female): Allows direct screw-on connection with male-threaded pipes or fittings.

- Materials:

- Carbon steel (ASTM A105)

- Stainless steel (304/316)

- Brass, bronze (for corrosion resistance)

- PVC/CPVC (for chemical/water applications)

- Pressure Rating: Typically Class 150 to Class 3000, depending on material and design.

2. Types & Variations

- Short Radius (SR): Compact design for tight spaces.

- Long Radius (LR): Smoother flow with reduced pressure drop.

- Street Elbow: One male-threaded end and one female-threaded end for direct pipe insertion.

3. Applications

- Plumbing & water supply systems

- Hydraulic & pneumatic systems

- HVAC & refrigeration lines

- Industrial process piping (low-pressure)

- Fire protection & gas distribution systems

4. Advantages

- Easy Installation: No welding required; simply screw onto threaded pipes.

- Removable/Reusable: Ideal for systems requiring maintenance or modifications.

- Leak-Resistant: Proper thread sealing (Teflon tape, pipe dope) ensures tight connections.

- Space-Saving: Compact design fits in confined areas.

5. Limitations

- Not suitable for high-pressure/temperature applications (compared to welded fittings).

- Threads may wear over time with frequent disassembly.

- Requires proper sealing to prevent leaks.

6. Standards & Compliance

- ASME B16.11 (Forged steel threaded fittings)

- ASTM A105/A182 (Material standards)

- MSS SP-83 (Threaded unions & elbows)

7. Installation Tips

- Use thread sealant (Teflon tape or pipe compound) to prevent leaks.

- Avoid over-tightening to prevent thread damage.

- Inspect threads for wear or corrosion before installation.

Why Choose an Internal Thread 90° Elbow?

This fitting is ideal for low-cost, easy-installation systems where frequent disassembly might be needed. Its threaded design eliminates welding, making it versatile for maintenance-heavy environments while ensuring a secure, directional flow change.

Factory

Product packaging

We can provide wooden box packaging, pallet packaging, carton box packaging, and we can accept customized packaging.

FAQ

Q:Can I Get A Sample For Testing?

A:Yes, We Can Provide Free Samples, But You Need To Pay For The Shipping Cost.

Q:Is It Safe On The Payment For Me As We Are The First Cooperation?

A:We Can Do The Trade Assurance On Alibaba, Which Will Guarantee Your Payment Safety, We Also Accept Other Safe Payment Way As You Want.

Q:Do You Accept Product Customization?

A:Yes, We Can Accept Material Customization, Specification Model Customization, Drawing Customization, Packaging Customization.

Q:Can I Put Our Logo On The Product?

A:Yes, We Can Provide You With Laser Engraving Logo And Sticker Logo For Free.

Q:What Is The Moq?

A:For Trial Order, We Can Sell Even One Piece

Q:How Long Is The Product Warranty Period?

A:One Year, If The Product Is Non-Artificially Damaged During The Warranty Period, We Can Provide You With A New Product For Free.

Q:How Long Is The Delivery Time?

A:If We Have Stock, We Will Ship Within 2 Days, If There Is No Stock, We Will Ship Within 5-7 Days.

Q:Do You Accept Oem/Odm Service?

A:Yes, We Can Produce Products According To Your Requirements.

Related Products

Product Consultation

We will contact you within one working day. Please pay attention to your email.