PRODUCTS

CONTACTS

Tel/WhatsApp: +8613315790503

Email: admin@shunlinfeng.com

Address: Yanshan County, Cangzhou, Hebei Province, China

Internal thread 90 degree M&F elbow

Product Detail

Standard

Product introduction

Internal Thread 90° M&F Elbow (Male & Female Threaded Elbow)

1. Product Definition

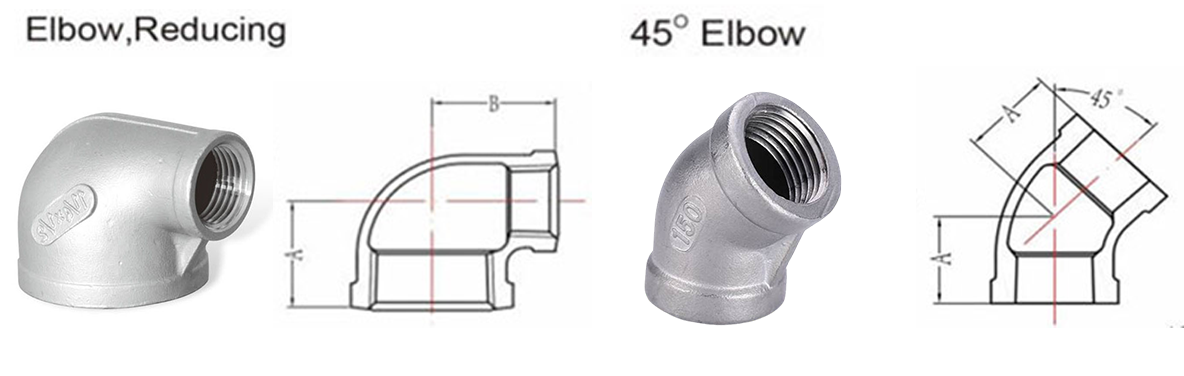

A 90-degree M&F threaded elbow is a pipe fitting designed to change flow direction at a right angle while featuring male (external) threads on one end and female (internal) threads on the other. This hybrid design enables direct connection between differently configured pipes/fittings without additional adapters.

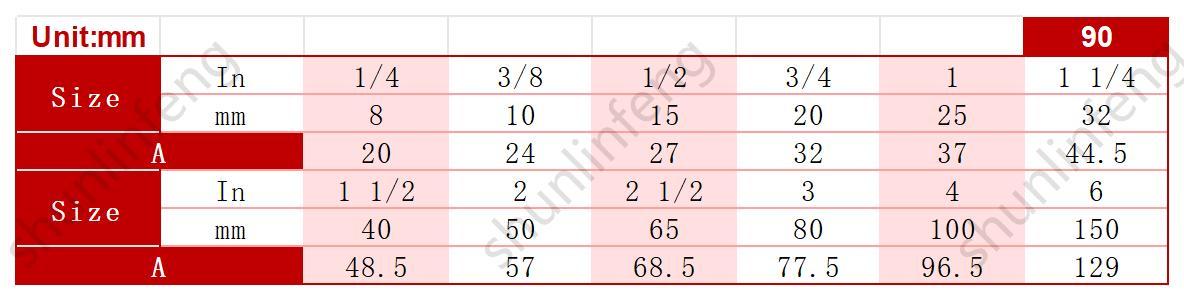

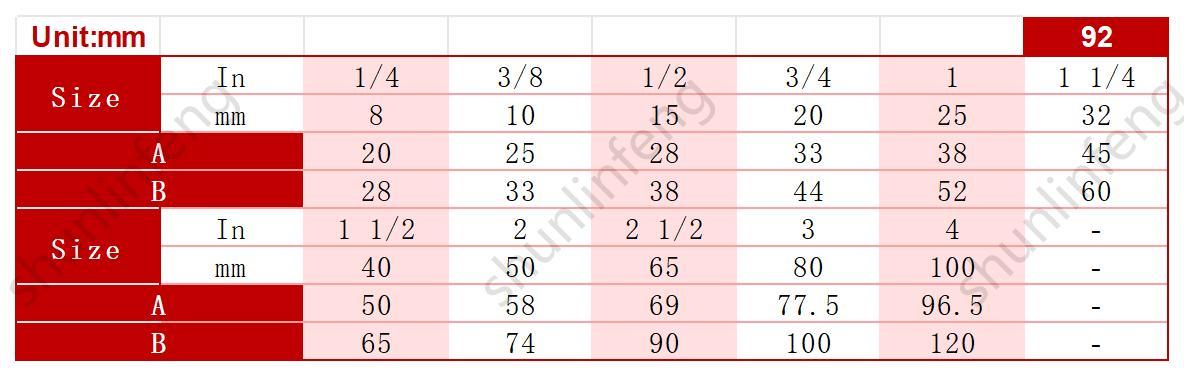

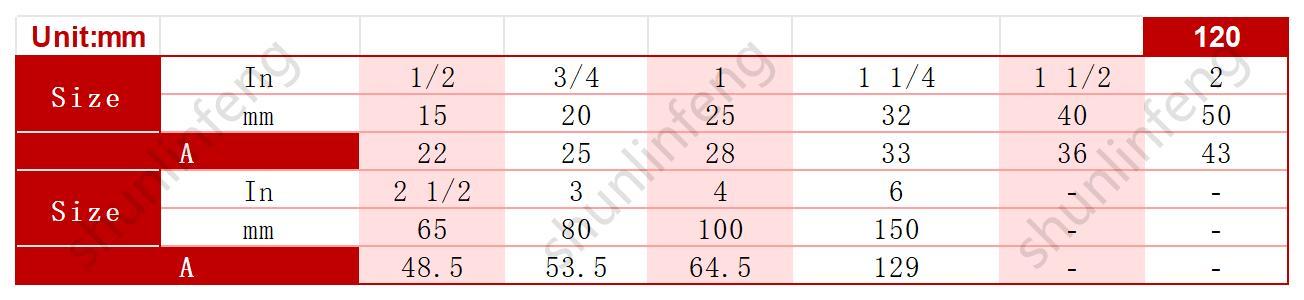

2. Key Specifications

- Connection Type:

- Female (F) End: Internal NPT/BSPT threads (typically conforming to ASME B1.20.1)

- Male (M) End: External tapered threads with sealant grooves

- Angle: Precise 90° turn (short-radius design standard)

- Materials:

- Carbon steel (ASTM A105)

- Stainless steel (A182 F304/316)

- Brass (UNS C36000)

- Forged construction per ASME B16.11

3. Design Advantages

- Space Optimization: Eliminates need for separate union/nipple

- Leak Prevention: Dual-thread design with proper sealant creates redundant sealing

- Installation Flexibility:

- Male end connects to female-threaded valves

- Female end accepts male-threaded pipes

- Vibration Resistance: Thread locking compounds enhance joint stability

4. Installation Protocol

1. Thread Preparation:

- Clean threads with wire brush

- Apply 2-3 wraps of PTFE tape (or equivalent thread compound)

2. Assembly:

- Hand-tighten male end first (minimum 3 full turns)

- Use strap wrench on hex flats (avoid pipe wrench marks)

3. Final Torque:

- Additional 1-1.5 turns with wrench

- Maximum torque per ASME B31.3 Table A-2B

5. Quality Assurance

- 100% thread gauge inspection (Go/No-Go)

- Hydrostatic tested to 1.5x rated working pressure

- Magnetic particle inspection (MPI) for forged steel units

6. Industry Applications

- Hydraulic Systems: Compact directional changes in manifolds

- Instrumentation: Connection of gauges/transmitters

- Fire Protection: Sprinkler system junctions

- Process Piping: Low-pressure chemical lines

7. Standards Compliance

- ASME B16.11: Forged fittings dimensions

- ASTM A105/A182: Material specifications

- MSS SP-114: Corrosion-resistant threading

Factory

Product packaging

We can provide wooden box packaging, pallet packaging, carton box packaging, and we can accept customized packaging.

FAQ

Q:Can I Get A Sample For Testing?

A:Yes, We Can Provide Free Samples, But You Need To Pay For The Shipping Cost.

Q:Is It Safe On The Payment For Me As We Are The First Cooperation?

A:We Can Do The Trade Assurance On Alibaba, Which Will Guarantee Your Payment Safety, We Also Accept Other Safe Payment Way As You Want.

Q:Do You Accept Product Customization?

A:Yes, We Can Accept Material Customization, Specification Model Customization, Drawing Customization, Packaging Customization.

Q:Can I Put Our Logo On The Product?

A:Yes, We Can Provide You With Laser Engraving Logo And Sticker Logo For Free.

Q:What Is The Moq?

A:For Trial Order, We Can Sell Even One Piece

Q:How Long Is The Product Warranty Period?

A:One Year, If The Product Is Non-Artificially Damaged During The Warranty Period, We Can Provide You With A New Product For Free.

Q:How Long Is The Delivery Time?

A:If We Have Stock, We Will Ship Within 2 Days, If There Is No Stock, We Will Ship Within 5-7 Days.

Q:Do You Accept Oem/Odm Service?

A:Yes, We Can Produce Products According To Your Requirements.

Related Products

Product Consultation

We will contact you within one working day. Please pay attention to your email.