PRODUCTS

CONTACTS

Tel/WhatsApp: +8613315790503

Email: admin@shunlinfeng.com

Address: Yanshan County, Cangzhou, Hebei Province, China

High-Pressure Threaded Pipe Couplings

Keyword:

Product Detail

Standard

Product introduction

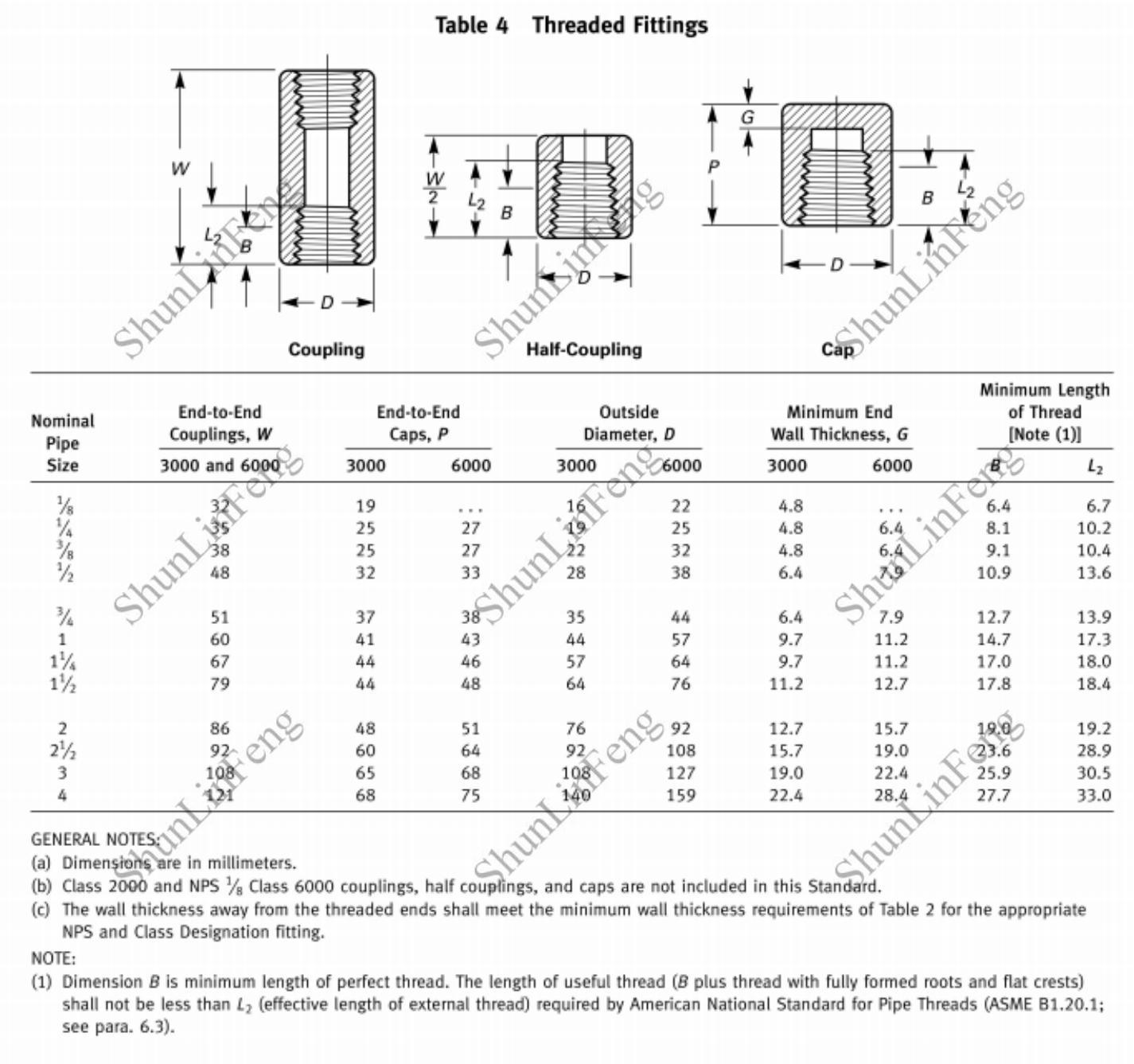

High-Pressure Threaded Pipe Couplings (Screwed Unions) – Technical Specification

1. Product Definition

A high-pressure threaded pipe coupling (screwed union) is a mechanical pipe connector designed to join two pipes in a straight run using precision-cut threads for systems operating at 1,000–10,000 psi. These fittings provide a separable joint while maintaining pressure integrity in critical applications where welding is impractical.

2. Design Features

✔ Heavy-Duty Threads: Rolled or machined threads with 30% deeper engagement than standard couplings for high-pressure resistance.

✔ Metal-to-Metal Seal: Tapered threads (NPT/BSPT) create a mechanical seal under tension.

✔ Hex Nut Design: Allows wrench tightening without damaging the pipe.

✔ Anti-Blowout Shoulder: Reinforced collar prevents thread stripping under extreme pressure.

✔ Optional Sealing Methods:

- PTFE tape (for NPT threads up to 3,000 psi)

- Liquid thread sealant (Loctite 545 for >5,000 psi)

- Metal sealing rings (for BSPP parallel threads)

3. Performance Advantages

- Quick Installation: No welding required—suitable for field repairs.

- Reusability: Can be disassembled and reassembled multiple times.

- Vibration Resistance: Thread-locking compounds prevent loosening in dynamic systems.

- Space Efficiency: More compact than flanged connections.

4. Installation Guidelines

1. Thread Preparation:

- Clean threads with a wire brush.

- Apply 2–3 wraps of PTFE tape (for NPT) or high-pressure sealant (e.g., Henkel 577).

2. Hand-Tightening:

- Engage threads fully by hand (minimum 3.5 turns for NPT).

3. Final Torque:

- Use a strap wrench to avoid thread damage.

- Tighten 1.5 turns past hand-tight (per ASME B31.3).

4. Pressure Testing:

- Hydro-test at 1.5× working pressure before full operation.

5. Industry Applications

- Oil & Gas: Wellhead control lines, hydraulic fracturing manifolds.

- Power Plants: Steam instrumentation lines.

- Chemical Processing: High-pressure reagent dosing systems.

- Aerospace: Fuel and hydraulic test rigs.

6. Quality & Compliance

- Material Certs: ASTM A105/A182 with 3.1 mill test reports.

- Thread Inspection: 100% GO/NO-GO gauge verification.

- Pressure Testing: Each unit hydro-tested per ASME B16.11.

- NACE MR0175: Compliant for sour (H₂S) environments.

7. Limitations

✗ Not for Cyclic Loading: Threads may fatigue under constant vibration.

✗ Limited to Small Pipes: Generally not used above 2" NPS for high-pressure.

✗ Sealant Dependency: Requires proper sealing to prevent leaks.

Factory

Product packaging

We can provide wooden box packaging, pallet packaging, carton box packaging, and we can accept customized packaging.

FAQ

Q:Can I Get A Sample For Testing?

A:Yes, We Can Provide Free Samples, But You Need To Pay For The Shipping Cost.

Q:Is It Safe On The Payment For Me As We Are The First Cooperation?

A:We Can Do The Trade Assurance On Alibaba, Which Will Guarantee Your Payment Safety, We Also Accept Other Safe Payment Way As You Want.

Q:Do You Accept Product Customization?

A:Yes, We Can Accept Material Customization, Specification Model Customization, Drawing Customization, Packaging Customization.

Q:Can I Put Our Logo On The Product?

A:Yes, We Can Provide You With Laser Engraving Logo And Sticker Logo For Free.

Q:What Is The Moq?

A:For Trial Order, We Can Sell Even One Piece

Q:How Long Is The Product Warranty Period?

A:One Year, If The Product Is Non-Artificially Damaged During The Warranty Period, We Can Provide You With A New Product For Free.

Q:How Long Is The Delivery Time?

A:If We Have Stock, We Will Ship Within 2 Days, If There Is No Stock, We Will Ship Within 5-7 Days.

Q:Do You Accept Oem/Odm Service?

A:Yes, We Can Produce Products According To Your Requirements.

Related Products

Product Consultation

We will contact you within one working day. Please pay attention to your email.