PRODUCTS

CONTACTS

Tel/WhatsApp: +8613315790503

Email: admin@shunlinfeng.com

Address: Yanshan County, Cangzhou, Hebei Province, China

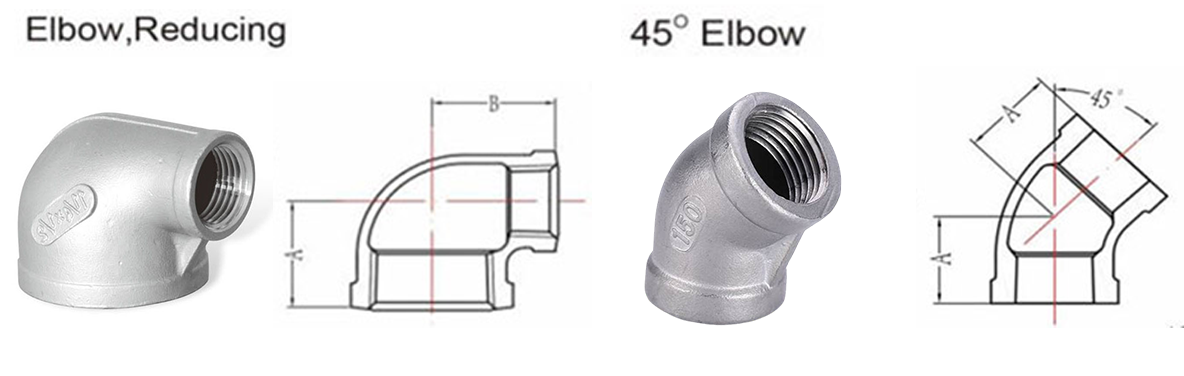

Internal thread 90 degree Reducing elbow

Product Detail

Standard

Product introduction

Internal Thread 90° Reducing Elbow

1. Product Definition

A 90-degree reducing elbow with internal threads is a specialized pipe fitting designed to:

Change flow direction by 90°

Transition between different pipe sizes

Provide female (internal) threaded connections at both ends

2. Key Specifications

Connection Type:

Internal NPT/BSPT threads at both inlet and outlet

Tapered threads conforming to ASME B1.20.1

Reduction Ratio:

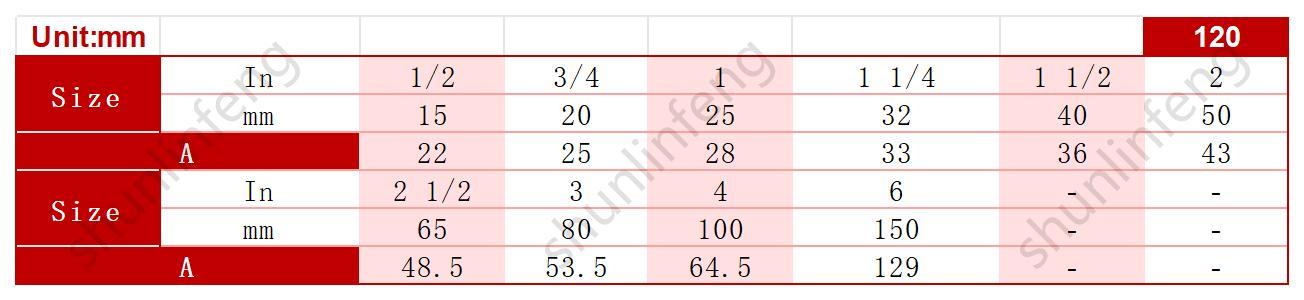

Standard step-down sizes (e.g., 1"×3/4", 2"×1-1/2")

Custom ratios available (max 2:1 reduction)

Materials:

Carbon steel (ASTM A105)

Stainless steel (A182 F304/316L)

Brass/bronze (for water service)

Forged construction per ASME B16.11

3. Design Features

Concentric Reduction: Smooth internal transition for minimal turbulenc

Reinforced Shoulder: Extra material at reduction point for strength

Full Thread Depth: Ensures proper engagement with male pipes

Hex Flats: Wrenching surfaces for easy installation

4. Performance Advantages

✔ Space Saving: Eliminates need for separate reducer + elbow

✔ Leak Resistance: Single-piece design reduces potential leak paths

✔ Flow Optimization: Gradual diameter change minimizes pressure drop

✔ Installation Efficiency: 50% faster than welded alternatives

5. Installation Guidelines

Thread Preparation:

Clean threads with appropriate brush

Apply thread sealant (PTFE tape for NPT, Loctite 567 for BSPT)

Assembly:

Hand-tighten both connections (minimum 3 full turns)

Final torque: 1/4 to 1/2 turn past hand-tight

Alignment Check:

Verify proper flow direction before pressurization

Support piping to prevent thread strain

6. Quality Assurance

100% thread gauge inspection

Hydrostatic tested to 1.5x rated pressure

Material certification per ASTM/ASME requirements

Surface inspection per MSS SP-55

7. Industry Applications

Water Treatment: Pipe size transitions in filter systems

HVAC: Refrigerant line directional changes

Industrial Plumbing: Chemical process lines

Oil & Gas: Instrumentation connections

8. Standards Compliance

ASME B16.11: Forged fittings standard

ASTM A105/A182: Material specifications

MSS SP-114: Corrosion-resistant requirements

NACE MR0175: For sour service applications

Note: For systems with vibration, recommend using:

Thread locking compounds (e.g., Loctite 242)

Secondary mechanical locking devices

Factory

Product packaging

We can provide wooden box packaging, pallet packaging, carton box packaging, and we can accept customized packaging.

FAQ

Q:Can I Get A Sample For Testing?

A:Yes, We Can Provide Free Samples, But You Need To Pay For The Shipping Cost.

Q:Is It Safe On The Payment For Me As We Are The First Cooperation?

A:We Can Do The Trade Assurance On Alibaba, Which Will Guarantee Your Payment Safety, We Also Accept Other Safe Payment Way As You Want.

Q:Do You Accept Product Customization?

A:Yes, We Can Accept Material Customization, Specification Model Customization, Drawing Customization, Packaging Customization.

Q:Can I Put Our Logo On The Product?

A:Yes, We Can Provide You With Laser Engraving Logo And Sticker Logo For Free.

Q:What Is The Moq?

A:For Trial Order, We Can Sell Even One Piece

Q:How Long Is The Product Warranty Period?

A:One Year, If The Product Is Non-Artificially Damaged During The Warranty Period, We Can Provide You With A New Product For Free.

Q:How Long Is The Delivery Time?

A:If We Have Stock, We Will Ship Within 2 Days, If There Is No Stock, We Will Ship Within 5-7 Days.

Q:Do You Accept Oem/Odm Service?

A:Yes, We Can Produce Products According To Your Requirements.

Related Products

Product Consultation

We will contact you within one working day. Please pay attention to your email.